Understanding Capacitor Converters: Units, Conversions & Applications

Capacitors, fundamental components in electronics, store electrical energy. But just like different units measure distances, capacitance is expressed using various units like picofarads (pF), nanofarads (nF), microfarads (μF), and farads (F). Understanding how to convert between these units is critical for anyone working with electronics. Additionally, a capacitor converter involves switching capacitors to achieve voltage transformation, a clever technique seen in many modern devices like phone chargers and power supplies. This article will guide you through these conversions and their uses, making the world of electronics a little easier to grasp, much like how we use miles vs kilometers in our daily lives.

Capacitance Units Explained: pF, nF, μF, and F

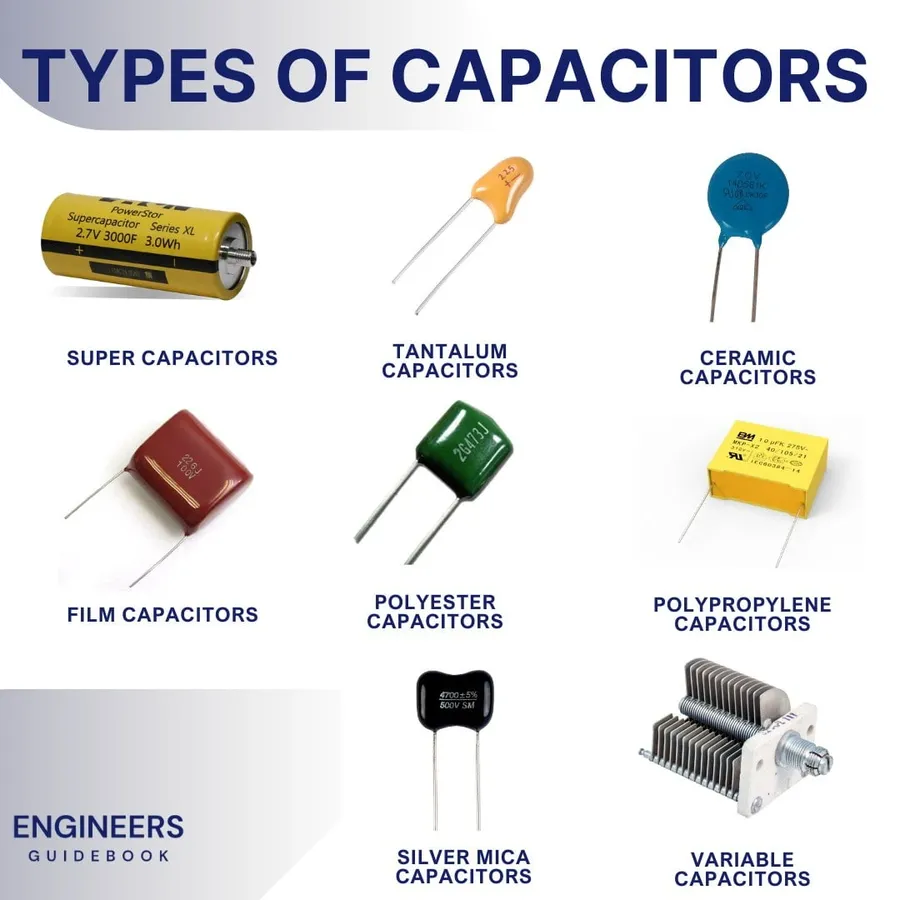

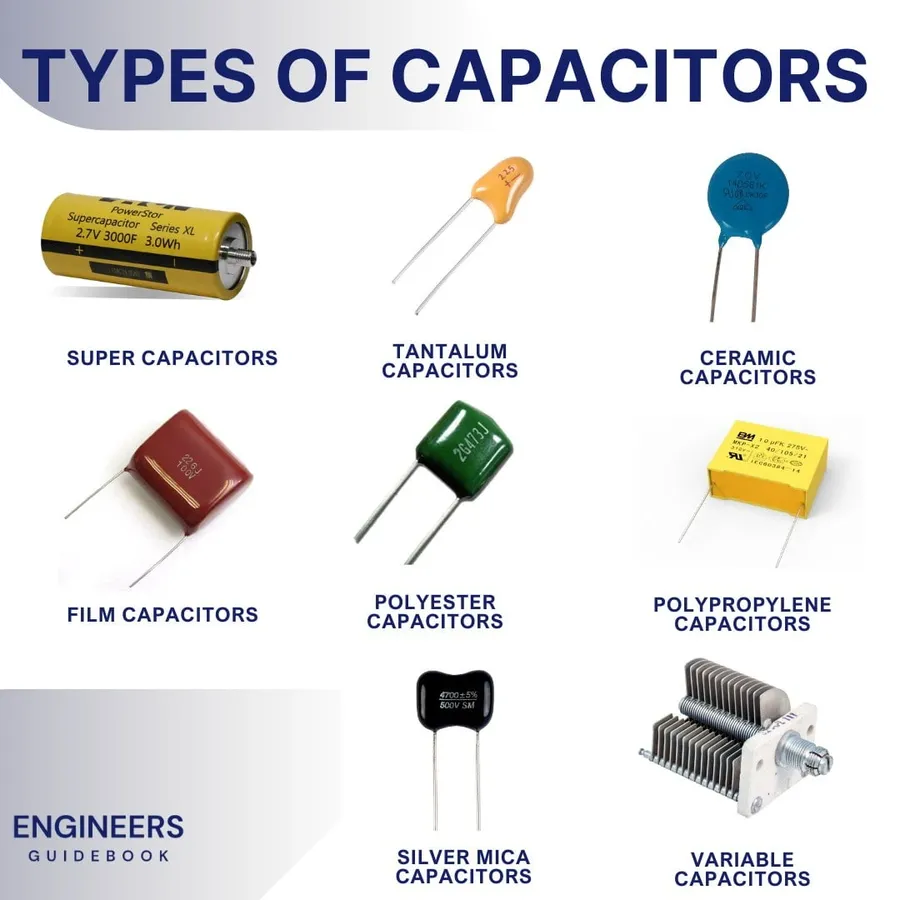

Various Capacitors

Capacitance, the ability of a component to store an electrical charge, is measured in Farads (F). However, a Farad is a very large unit, so in practical electronics, we commonly encounter smaller units: picofarads (pF), nanofarads (nF), and microfarads (μF). Understanding the relationships between these units is crucial for anyone working with electronic circuits.

| Unit | Abbreviation | Value in Farads (F) | Analogy |

|---|---|---|---|

| Picofarad | pF | 1 x 10^-12 F | Like a tiny droplet of water compared to a large pool |

| Nanofarad | nF | 1 x 10^-9 F | Like a small cup of water compared to a large pool |

| Microfarad | μF | 1 x 10^-6 F | Like a small bucket of water compared to a large pool |

| Farad | F | 1 F | Like an Olympic sized swimming pool |

The Need for Capacitor Conversion

Capacitor conversion is essential in electronics due to the varied ways capacitance is specified and the practical needs of circuit design, component selection, and repair. The necessity arises from the diverse range of capacitance units used (picofarads (pF), nanofarads (nF), microfarads (µF), and farads (F)) and the need to interpret datasheets, ensuring proper component matching during manufacturing, design and repair processes.For example, a capacitor might be listed as 2200 pF on a schematic, but a parts supplier may only list available parts in nF or µF. Therefore, it would be essential to convert 2200 pF to 2.2 nF or 0.0022 µF to find a suitable component. Similarly, datasheets from different manufacturers might use different units, making direct comparison difficult without proper conversions. This demonstrates that unit conversions are not just theoretical exercises but crucial practical requirements for a functional system.

Consider a common application such as a smartphone circuit. Designers often work with values in pF for high-frequency circuits and in µF for power supply decoupling. To combine these components in a single circuit requires accurate conversion between units to calculate the effective capacitance and ensure the circuit behaves correctly. Repair technicians also encounter this when replacing parts or analysing circuits. Without a clear understanding and facility with unit conversion, it becomes extremely hard to correctly troubleshoot the issue or replace components correctly. Thus, facility in unit conversion is crucial for working with electronic circuits and components.

Basic Capacitance Conversion Formulas

Capacitance Unit Conversion

Capacitance values are expressed in various units, most commonly picofarads (pF), nanofarads (nF), microfarads (µF), and farads (F). Converting between these units is essential in electronics for design, analysis, and component selection. The conversions are based on powers of ten, where each unit represents a multiple of the base unit, the farad.

| Conversion | Formula | Example |

|---|---|---|

| pF to nF | nF = pF / 1000 | 1000 pF = 1 nF |

| pF to µF | µF = pF / 1,000,000 | 1,000,000 pF = 1 µF |

| pF to F | F = pF / 1,000,000,000,000 | 1,000,000,000,000 pF = 1 F |

| nF to pF | pF = nF * 1000 | 1 nF = 1000 pF |

| nF to µF | µF = nF / 1000 | 1000 nF = 1 µF |

| nF to F | F = nF / 1,000,000,000 | 1,000,000,000 nF = 1 F |

| µF to pF | pF = µF * 1,000,000 | 1 µF = 1,000,000 pF |

| µF to nF | nF = µF * 1000 | 1 µF = 1000 nF |

| µF to F | F = µF / 1,000,000 | 1,000,000 µF = 1 F |

| F to pF | pF = F * 1,000,000,000,000 | 1 F = 1,000,000,000,000 pF |

| F to nF | nF = F * 1,000,000,000 | 1 F = 1,000,000,000 nF |

| F to µF | µF = F * 1,000,000 | 1 F = 1,000,000 µF |

Understanding these conversions is crucial for working with datasheets and designing circuits. The table above provides an easy reference for common conversions. For manual calculations, carefully apply the formulas, paying close attention to the powers of ten.

Switched Capacitor Voltage Converters: An Overview

Switched Capacitor Voltage Converter Chip

Switched capacitor voltage converters, also known as charge pumps, represent a highly efficient and compact method of DC-DC voltage conversion, leveraging capacitors as the primary energy storage element rather than inductors. Their operation relies on the controlled switching of capacitors to transfer charge, thereby altering the voltage level. This approach significantly enhances energy efficiency, particularly in low-power applications, and simplifies design by eliminating the need for bulky inductors, making them ideally suited for modern, miniaturized electronic devices.

Traditional linear regulators, while simple, suffer from significant power dissipation as heat, especially when there's a substantial difference between input and output voltages. In contrast, switched capacitor converters minimize this loss by transferring charge between capacitors, resulting in significantly improved energy efficiency. This improvement is a key factor in extending battery life and reducing heat generation in portable electronic devices.

The fundamental principle of switched capacitor converters involves periodically charging a capacitor and then transferring this stored charge to another capacitor in a different voltage level. The switching action is precisely timed and controlled to achieve the desired voltage conversion ratio. These converters can be designed to step up, step down, or invert voltages, making them incredibly versatile for a wide array of applications.

Furthermore, the absence of inductors not only reduces size and weight but also minimizes electromagnetic interference (EMI), a crucial consideration in sensitive electronic environments. Switched capacitor converters are also inherently more cost-effective to manufacture due to their simplicity and use of standard capacitor technology. This combination of high efficiency, small size, low EMI, and reduced cost positions switched capacitor converters as a preferred choice in many modern applications where these attributes are crucial. Their applications range from powering microcontrollers and sensors to driving LED displays and audio amplifiers.

Types of Switched Capacitor Converter Configurations

Switched Capacitor Converter Circuit

Switched capacitor converters utilize different circuit topologies to achieve varied voltage transformations. These configurations, such as voltage inverters, voltage doublers, and charge pumps, offer unique advantages and are chosen based on specific application requirements. Understanding these topologies is crucial for effective circuit design.

| Topology | Function | Description | Applications |

|---|---|---|---|

| Voltage Inverter | Inverts the polarity of the input voltage. | Produces a negative voltage from a positive input. Ideal for generating negative supply rails for op-amps or other circuits needing bipolar supplies. | Op-amp power supplies, RS-232 converters, negative bias generation |

| Voltage Doubler | Multiplies the input voltage by approximately two. | Achieves a higher output voltage than the input, efficient for low current applications. | LED drivers, low-power sensors, portable electronics |

| Charge Pump | Transfers charge between capacitors to increase or decrease voltage. | Versatile in generating different voltage levels. It uses switching and charge transfer to achieve desired voltage conversions. | Microprocessor voltage regulators, powering low power ICs, memory circuits |

Practical Applications of Capacitor Converters

Smartphone Circuit Board

Capacitor converters, also known as switched capacitor converters or charge pumps, have become ubiquitous in modern electronics due to their efficiency, small size, and simplicity. These devices facilitate the conversion of voltage levels without the need for bulky inductors, making them ideal for portable and space-constrained applications. Their core function is to transfer energy between capacitors to achieve the desired voltage conversion.

- Smartphones and Mobile Devices

Capacitor converters are extensively used in smartphones for various purposes. They power low-voltage circuits such as LEDs, sensors, and audio amplifiers, efficiently stepping down the battery voltage to required levels. These converters are also essential in managing the power supply to the processor and other integrated circuits, ensuring optimal performance and battery life. - Digital Cameras and Imaging Systems

In digital cameras, capacitor converters provide stable and efficient voltage supplies for image sensors, display screens, and other electronic components. They allow for compact and lightweight designs, which are critical for portability and user comfort. The converters' high-efficiency operation contributes to extending battery life, which is a key performance characteristic for camera users. - Portable Electronic Devices

A wide range of portable devices such as tablets, laptops, and wearables rely on capacitor converters. They play a pivotal role in power management, ensuring efficient voltage conversion for different sub-systems. Their small footprint allows for the integration of more features within these devices, enhancing their functionality. - LED Lighting

Capacitor converters are also found in LED lighting applications. They can boost or step down voltage levels to match the requirements of LEDs efficiently. Their low component count, combined with high performance, contributes to the widespread adoption of LEDs, particularly in portable devices. The absence of inductors also results in quieter operation, which is a key requirement for many environments. - Automotive Electronics

Capacitor converters are increasingly finding applications in automotive electronics, supporting the operation of various control systems, sensors, and display units. Their efficiency and compact size are especially advantageous in the demanding and often space-constrained environments within vehicles. They also play a key role in managing power distribution throughout various systems.

Choosing the Right Capacitor Converter: Key Considerations

Selecting the appropriate capacitor converter for a given application requires a careful analysis of several key factors. These include efficiency, size limitations, cost, and the desired voltage transformation ratio. A thorough understanding of these aspects is crucial to ensure optimal system performance and cost-effectiveness.| Topology | Efficiency | Size | Cost | Voltage Transformation Ratio | Typical Applications |

|---|---|---|---|---|---|

| Voltage Inverter | Moderate | Small | Low | -1 | LCD bias, simple negative supply |

| Voltage Doubler | Moderate to High | Small to Medium | Low to Moderate | 2 | LED drivers, low-power boosting |

| Charge Pump | Moderate to High | Small to Medium | Low to Moderate | Integer ratios (e.g. 1/2, 2, 3/2 etc.) | Bias supplies for op-amps, powering small circuits |

| Fractional Converters | Moderate | Medium | Moderate | Fractional step up/down (e.g., 1.5, 0.67) | Advanced PMIC functions |

| Regulated Switched Capacitor Converters | High | Medium to Large | Moderate to High | Adjustable Voltage | Precise Voltage regulation, sensitive analog circuits |

- Efficiency

Capacitor converter efficiency is determined by how much of the input power is converted into useful output power, with losses primarily due to resistive components and switching activity. Higher efficiency translates into less heat generation and a longer battery life in portable applications, making it a crucial consideration when power budgets are tight. A common way to measure efficiency is the ratio of output power to input power. In most cases the higher the better. - Size Constraints

In compact devices, the size of the capacitor converter is critical. Designers must balance efficiency with the physical footprint of the required components, opting for smaller and more integrated solutions. The size of the capacitors and the integrated circuit containing the switches will determine the physical dimensions of the device. The more power being converted, the larger the components tend to be, so a smaller power budget might be required. - Cost

The cost of the capacitor converter circuit is an important consideration, often impacting the overall cost of the final product. Basic converters such as inverters and charge pumps have relatively low cost, while more complex regulated circuits can have a much higher cost due to additional components and control circuits, which can affect both the BOM costs and the design costs. As a general rule of thumb, more functionality, better regulation, and higher efficiency will increase costs. - Voltage Transformation Ratio

The desired voltage transformation ratio dictates the type of capacitor converter that can be used. Inverters, doublers, charge pumps, or more complex fractional ratio converters are selected based on this specification. Understanding the input to output voltage ratio is the cornerstone of choosing the correct switched capacitor converter.

Frequently Asked Questions about Capacitor Conversions and Converters

This section addresses common questions regarding capacitor conversions and switched capacitor converters, providing clear, concise answers to enhance understanding and practical application.- What is the conversion from picofarads (pF) to microfarads (µF)?

To convert from picofarads (pF) to microfarads (µF), divide the value in pF by 1,000,000. This is because 1 µF equals 1,000,000 pF. For example, 1,000,000 pF equals 1 µF. - Why is it necessary to convert between different units of capacitance?

Capacitance values are expressed in different units (pF, nF, µF, F) to accommodate the wide range of capacitor sizes used in electronics. Conversions are necessary to understand datasheets, match components for circuit design, and ensure proper operation within various applications. Using consistent units simplifies calculations and prevents errors. - What are switched capacitor voltage converters?

Switched capacitor voltage converters, also known as charge pumps, are electronic circuits that use capacitors as energy storage elements to convert a DC voltage to another DC voltage, typically higher or inverted. They are favored for their small size, low cost, and lack of inductors. - How do switched capacitor voltage converters work?

Switched capacitor voltage converters operate by charging capacitors in parallel and then discharging them in series or in a different configuration to achieve the desired voltage level. This process is managed by electronic switches operating at high frequency, which results in the effective transfer of charge and, consequently, a change in the voltage. - What are the advantages of switched capacitor converters over traditional linear voltage regulators?

Switched capacitor converters have several advantages, including higher efficiency in certain applications (especially for small voltage ratios), smaller size, lower cost, and the absence of inductors, which makes them suitable for compact electronic devices. However, they can have higher output ripple and are not ideal for high-current applications compared to linear voltage regulators. - What are common applications for switched capacitor converters?

Switched capacitor converters are commonly found in battery-powered devices such as smartphones, tablets, digital cameras, and wearable technology. They are also used in LCD bias power supplies, memory programming circuits, and various other voltage conversion applications where size, cost, and efficiency are critical. - What should I consider when choosing a capacitor for a switched capacitor converter?

When selecting capacitors for a switched capacitor converter, critical considerations include voltage rating, capacitance value, equivalent series resistance (ESR), and temperature characteristics. The capacitance value directly influences the converter's energy storage capacity, while ESR affects power loss and efficiency. It is crucial to choose capacitors that meet the application's operational requirements and are within the specification range of the converter.